Close

Keeping the water in our lakes, rivers, and streams clean requires monitoring of water quality at many points as it gradually makes its way from its source to our oceans. Over the years ever increasing environmental concerns and regulations have heightened the need for increased diligence and tighter restrictions on wastewater quality. Control of water pollution was once concerned mainly with treating wastewater before it was discharged from a manufacturing facility into the nation’s waterways. Today, in many cases, there are restrictions on wastewater that is discharged to city sewer systems or to other publicly owned treatment facilities. Many jurisdictions even restrict or regulate the runoff of stormwater — affecting not only industrial and commercial land, but also residential properties as well.

In its simplest form, water pollution management requires impoundment of stormwater runoff for a specified period of time before being discharged. Normally, a few simple tests such as pH and suspended solids must be checked to verify compliance before release. If water is used in any way prior to discharge, then the monitoring requirements can expand significantly. For example, if the water is used for once-through cooling, testing may include temperature, pH, total dissolved solids (TDS), chemical oxygen demand (COD), and biochemical oxygen demand (BOD), to name a few.

Once water is used in a process, some form of treatment is often required before it can be discharged to a public waterway. If wastewater is discharged to a city sewer or publicly owned facility, and treatment is required, the quality is often measured and the cost is based not only on the quantity discharged, but also the amount of treatment required. As a minimum requirement suspended solids must be removed. Such removal is often accomplished by filtering or using clarifiers. Monitoring consists of measuring total suspended solids (TSS) or turbidity.

If inorganic materials have been introduced into the water, their concentration must be reduced to an acceptable level. Inorganics, such as heavy metals, typically are removed by raising the pH to form insoluble metal oxides or metal hydroxides. The precipitated contaminants are filtered or settled out. Afterward, the pH must be adjusted back into a “normal” range, which often requires continuous monitoring of pH.

Organic materials by far require the most extensive treatment. Many different methods have been devised to convert soluble organic compounds into insoluble

inorganic matter. Most of these involve some form of biological oxidation treatment. Bacteria are used to metabolize the organic materials into carbon dioxide and solids, which can be easily removed. To insure that these processes work smoothly and efficiently requires regular monitoring of the health of the biological organisms. The level of food (organic material), nutrients (nitrogen and phosphorous), dissolved oxygen, and pH are some of the parameters that must be controlled. After bio-oxidation the wastewater is filtered or clarified. Often the final effluent is treated with an oxidizing compound such as chlorine to kill any remaining bacterial agents, but any excess oxidant normally must be removed prior to discharge. Oxidation Reduction Potential (ORP)/Redox is ideal for monitoring the level of oxidants before and after removal. The final effluent stream must be monitored to make sure it meets all regulatory requirements.

The monitoring of wastewater pollution does not end there. Scientists are continuously testing water in streams, ground water, lakes, lagoons, and other bodies of water to determine if and what effects any remaining contamination is having on the receiving waters and its associated aquatic life. Measurements may include pH, conductivity, TDS, temperature, dissolved oxygen, TSS and organic levels (COD and BOD).

Environmental testing is not limited to monitoring of wastewater systems. Control of air emissions often includes gas-cleaning systems that involve the use of water. Wet scrubbers and wet electrostatic precipitators are included in this group. A flue gas desulfurization (FGD) system is one type of wet scrubber that uses a slurry of lime, limestone, or other caustic material to react with sulfur compounds in the flue gas. The key to reliable operation of these units is proper monitoring of solids levels and pH. After use, the water in these systems must be treated or added to other wastewater from the plant, where it is treated by one of the methods previously discussed.

With proper monitoring, systems that maintain cleaner air and water can be operated efficiently and effectively. Such operation will go a long way toward maintaining a cleaner environment for us and future generations.

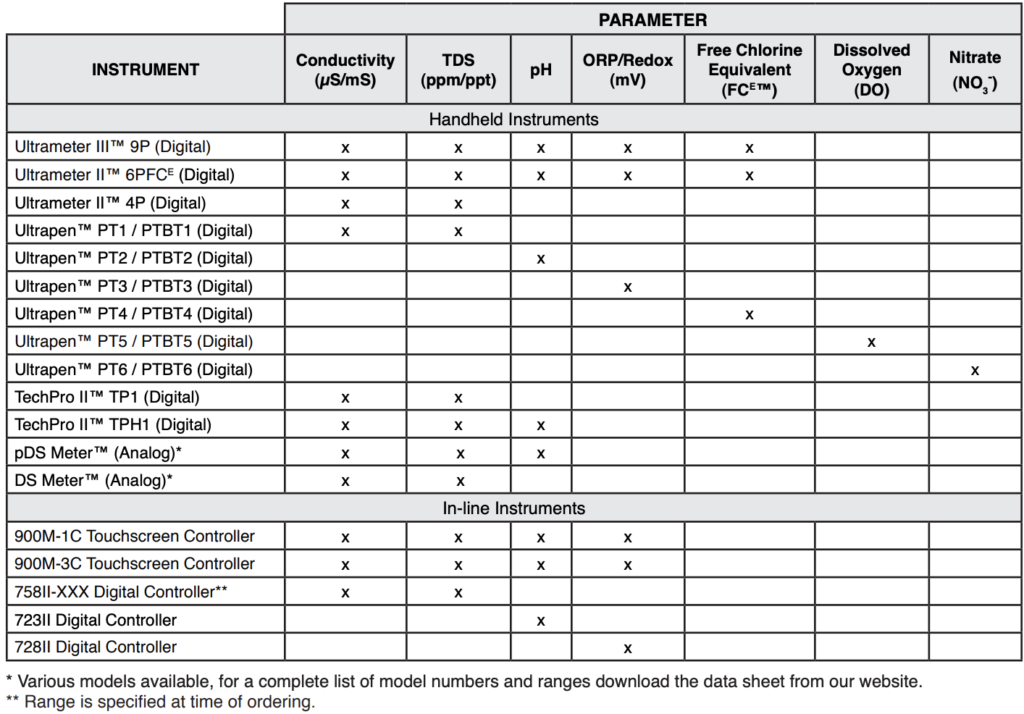

The Myron L® Company offers a full line of handheld instruments and in-line monitor/controllers that can be used to measure or monitor many of the parameters previously mentioned.

Note: When using a monitor/controller to measure pH in streams that contain heavy metals, sulfides, or other materials that react with silver, Myron L® recommends using a double junction pH sensor with a potassium nitrate (KNO3) reference gel to avoid fouling the silver electrode. Refer to sensor data sheets or contact your local distributor or the Myron L® Company.

The following table briefly covers some of the Myron L® Company instruments recommended for common environmental applications. For further details, please contact your local distributor, refer to Myron L® data sheets, visit our website (www.myronl.com), or contact us by phone, fax, or email (sales@myronl.com).